previous page

Next page

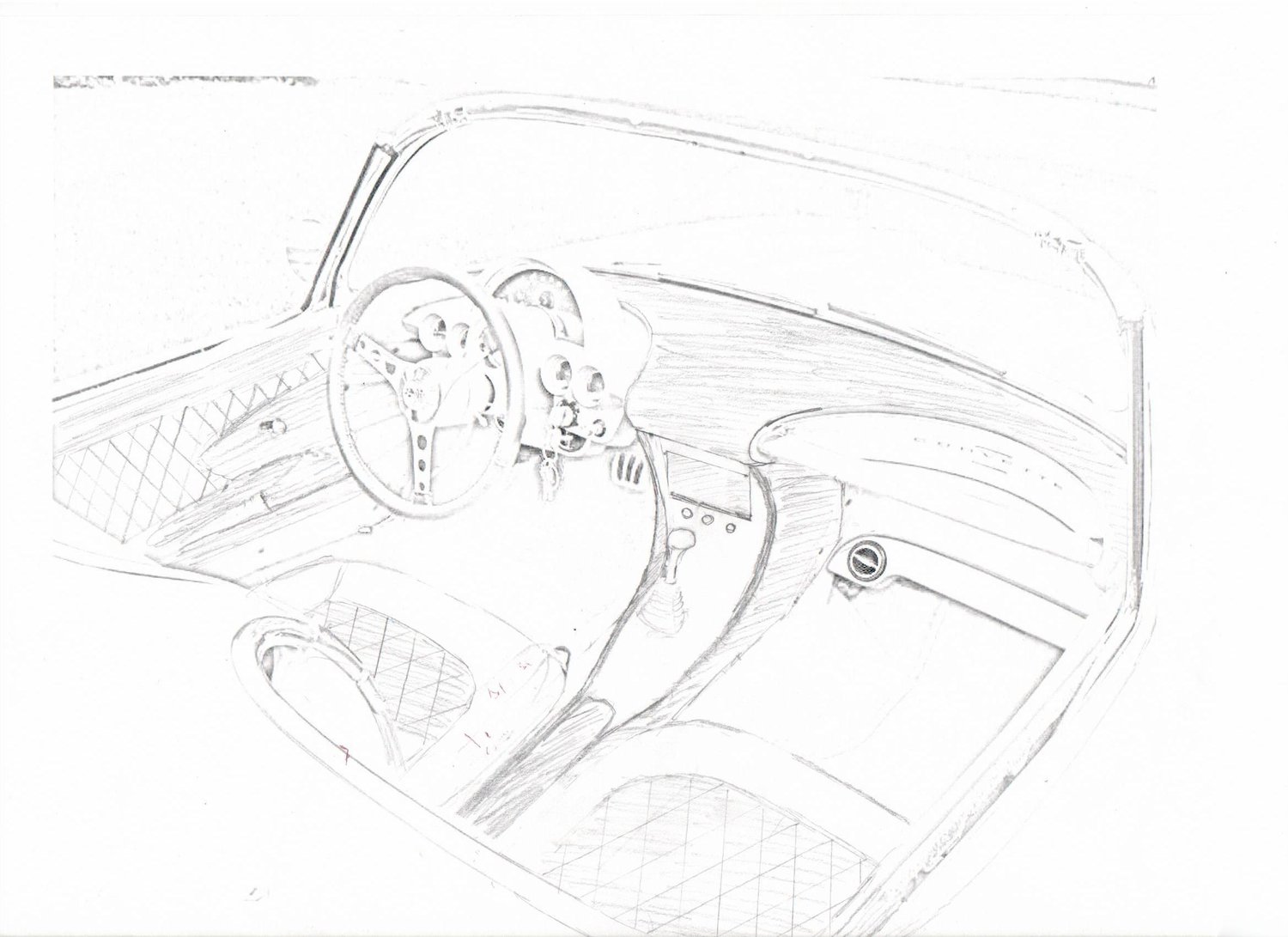

Interior Design

A clear understanding between the client and our team is made to determine the style and colors desired for interior.

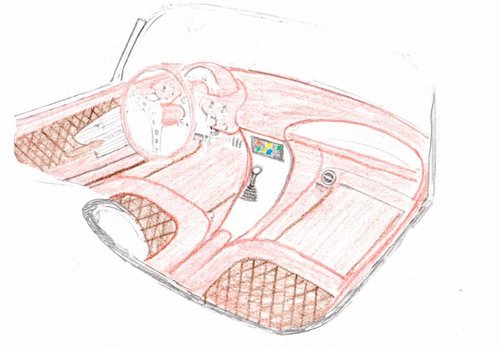

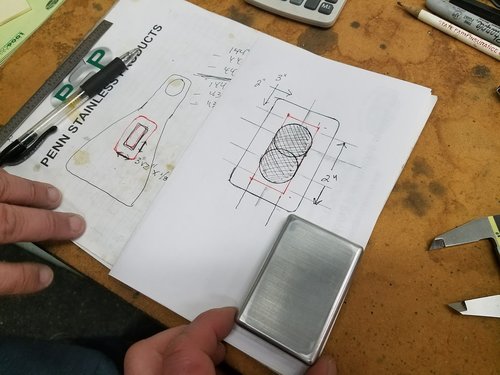

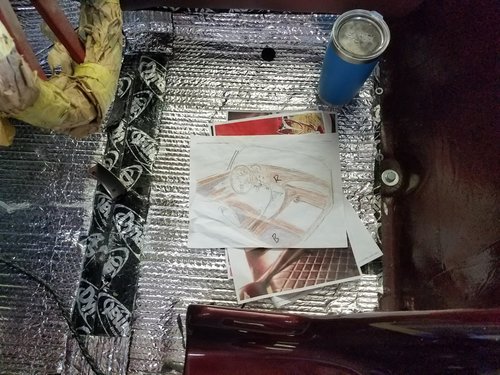

Often a drawing will be needed to conceptualize the desired design.

The client will often provide pictures of a style desired like the lower left below, then we can create it into form and integrate it into the overall design.

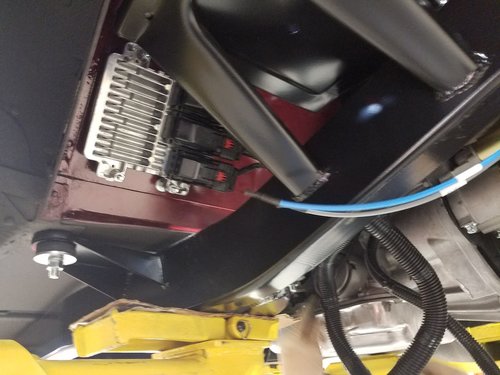

Templates for placement and actual placement of components is laid out to ensure a good function.

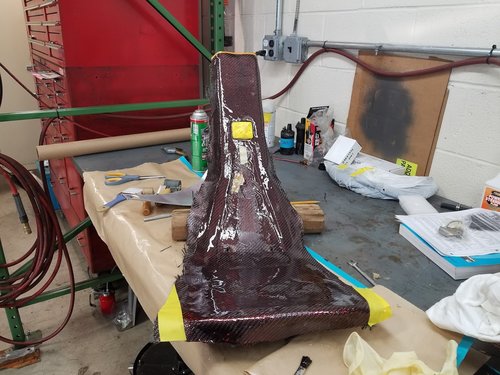

Custom made components like this console are now fabricated.

The transmission tunnel is also narrowed for more interior leg room.

Alot goes into handmade custom parts. Many stages are needed in the design and fabrication for a custom interior to not only look great but function with durability.

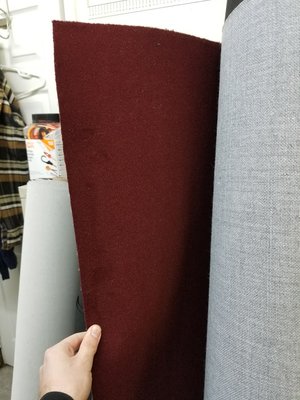

The interior material has been selected and acquired. In this instance the highest quality premium leather used. On this build two tones are used.

The panels are ten cover for the console and installed.

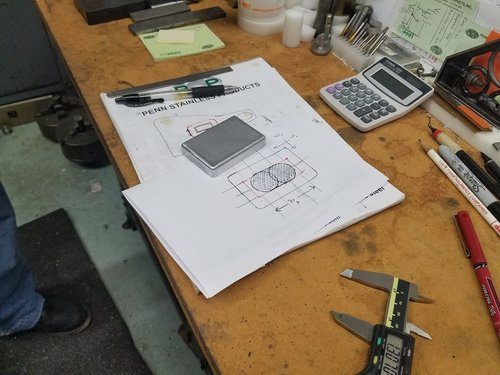

All design work is completed and parts fabricated and machined.

A modern HVAC unit is installed that will blow ice cold to hot air evenly around passengers.

Custom seat frames are made on this build to perfectly fit the area and extreme comfort for passengers.

All surfaces are prepared for covering. foam cushioning is then made. Based on the drawing and conceptual design, Mock up seat covers and dash pad are made for templates for the leather coverings.

The leather coverings are carefully and expertly created and installed.

All electronics are now installed and the car will be brought to a running and driving condition.

All door, kick and trunk panels are covered and a carpet set is made from the finest materials. Speial touches like this custom made die stamp are made for the client.

The interior is then fully test fit.